You are here: Start » Tutorial Exercises » Bottle Inspector Part 3: Foam Detection

Bottle Inspector Part 3: Foam Detection

Aim:

- Extend the "Bottle Inspector Part 2" program with verification to ensure there is no foam above the liquid level.

- Design a simple HMI that presents all the inspection results in the end-user's graphical interface.

Input

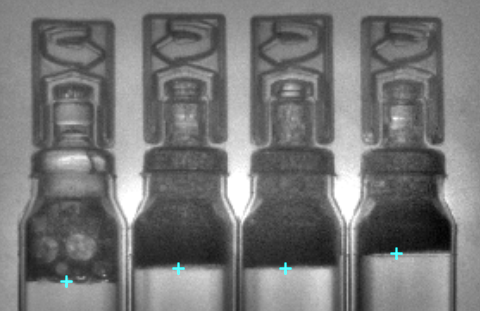

- A set of images of bottles.

- An array of liquid level points from the previous exercise.

Images are stored in the bottles directory.

Output:

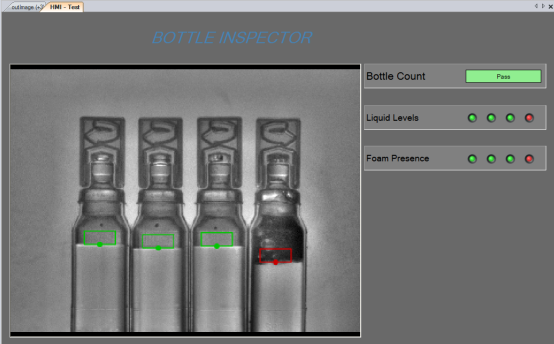

Application with an HMI which performs several inspections:

- Checking of the number of bottles,

- Validation of the liquid levels,

- Detection of foam above the liquid levels.

The results should be presented in the HMI, visualized with green or red primitives.

Hints:

The foam is much darker than the normal interior of a bottle above the liquid level.

In the first step, use the CreateRectangle filter to create a ROI based on previously calculated liquid level points.

Measure the average intensity within the ROI with the CheckPresence_Intensity.

Create a simple HMI form:

Solution (FIS)

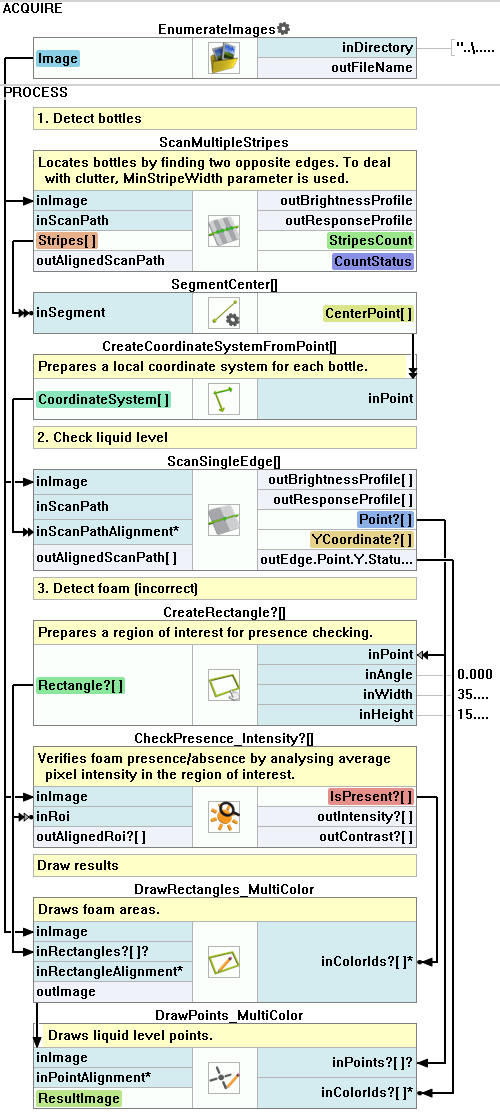

Start with the program created in the "Bottle Inspector Part 2" tutorial.

-

Add the CreateRectangle filter:

- Connect its inPoint input with the output representing liquid level points.

- Set its inPointAnchor input to BottomCenter.

- Set the inWidth and the inHeight to 35 and 15 respectively.

-

Add CheckPresence_Intensity filter and connect its inImage input with the input image and the inRoi with the created rectangle.

-

Set the inMinIntensity input to 80.

-

Draw results of the performed inspections with red and green colors depending on the inspection result. Use the DrawRectangles_MultiColor and the DrawPoints_MultiColor filters for that.

Macrofilter Main performs all inspections and shows results on the HMI.